![]() — available at Smith & Larson Audio —

— available at Smith & Larson Audio —

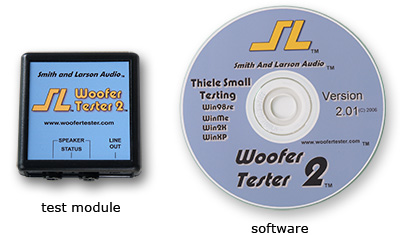

The Woofer Tester 2 (WT2) by Smith & Larson Audio is an affordable tool that measures the Thiele-Small (T-S) parameters of speaker drivers with professional precision. In addition to woofers, it can also measure many midrange drivers and tweeters. It includes two parts: (1) a test module that connects to the USB port of your computer and (2) software to control the test module. The test module is small, very portable, and is powered by the USB port (no batteries or AC adapter are required or provided). It has a true current source drive with a continuously adjustable sinewave output from 1 Hz to 20 kHz and can measure impedance and phase with an accuracy of 0.01 ohm and 0.1 degree. It is equally "at home" on a test bench with a desktop PC or in the field with a notebook PC. Please read on to learn about its many capabilities.

Easy Single-Button Testing

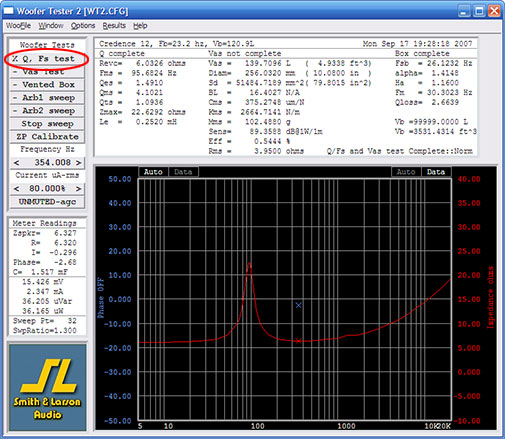

The WT2 software is designed for both ease and efficiency. Most tests can be performed with the press of a single button on screen. For example, press the "Q, Fs test" button circled below to test the Qms, Qes, Qts and Fs of a driver. The driver Le will also be measured.

Notice above that the driver's impedance response is displayed after the test. The graph also serves to indicate the progress during a test.

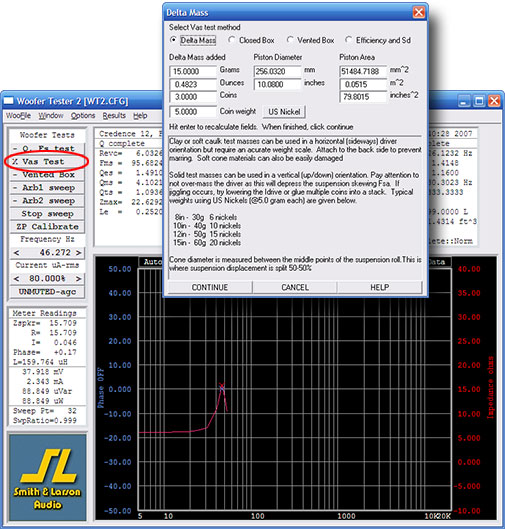

Press the "Vas Test" button circled below to test the Vas of a driver. The small dialog shown on top below will open so you can select one of four test methods: (1) Delta Mass, (2) Closed Box, (3) Vented Box, and (4) Efficiency and Sd. It also requires you to enter the piston diameter or area of the driver. The first method (Delta Mass) is very easy to use when the driver is laying on its back because you can use coins to add mass since most coins have a known weight. For example, U.S. nickels are very close to 5 grams each and the description in the dialog box provides some guidelines for how many nickels to use for different size woofers. The second and third methods (Closed Box and Vented Box) are both "delta compliance" methods. The last method (Efficiency and Sd) is helpful when testing tweeters and compression drivers.

In addition to Vas, the "Vas Test" also measures the driver's BL, Mms, Cms, Rms, efficiency, sensitivity, Krm, Erm, Kxm, and Exm.

The WT2 also provides single-button analysis of a vented box to find its effective volume (Vb) and tuning frequency (Fsb).

Measure and Simulate Rem/Xem Frequency-Dependent Reactance

The WT2 offers an alternate method to determine T-S parameters using Rem/Xem curve-fitting to measure a "bare" T-S tank circuit. It can produce a superior T-S model and simulation for larger drivers like woofers and subwoofers. Initial Rem and Xem values are determined during the "Q, Fs test". They are refined during the "Vas Test".

Measure Resistors, Inductors and Capacitors

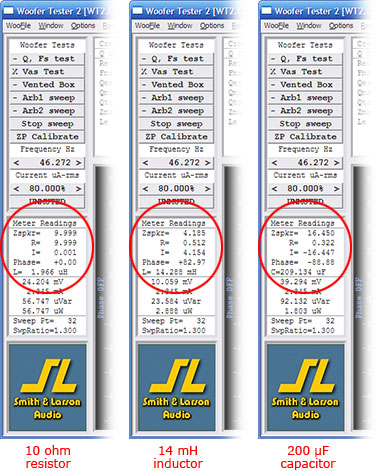

Notice in the images below that the WT2 has a "Meter Readings" section (circled in red in each picture). It provides an instantaneous readout of impedance (Zspkr) of any load that is connected to the test module. Since impedance is a "complex" characteristic with both "real" and "imaginary" parts, the "Meter Readings" section also breaks down the impedance into its real (R) and imaginary (I) values and displays the phase angle (Phase) that results. Based on these real and imaginary values, it determines if the load reactance is primarily inductive or capacitive and it displays the inductance (L) or capacitance (C) at the bottom. This is a very powerful tool that enables you to measure a variety of devices, including resistors, inductors and capacitors.

In the three examples above, a 10 ohm resistor, 14 mH inductor and 200 µF capacitor were each connected to the WT2 so you can see the measured results above. Also notice that you can obtain the resistive component of inductors (DCR) and capacitors (ESR) from the "real" (R) readout. In the above examples, the inductor measured 14.288 mH and had a DCR of 0.512 ohms. The capacitor measured 209.134 µF and had an ESR of 0.322 ohms.

Measure the Inductance of Speaker Cables and Test Leads

Using the same "Meter Readings" described above, you can measure other devices. For example, you can measure the inductance of speaker cables, test leads, etc. Plus you can plot the impedance and phase versus frequency and observe the effect of inductance at higher frequencies. This is a great tool when evaluating speaker wire.

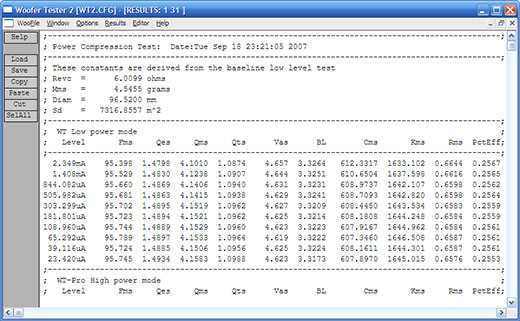

Measure the Non-Linearity of T-S Parameters versus the Drive Level

By their nature, some speaker drivers are not very linear. The best ones are reasonably linear over the widest possible range of excursion but as the excursion increases and the suspension is stretched, the compliance (Cms) of nearly all drivers will change and this also changes their resonance (Fs). The WT2 provides a way to measure a portion of this change so you can select the best drivers with the greatest linearity (least change). To accomplish this, the WT2 measures 10 sets of free-air T-S parameters while the output is incrementally stepped down to 1/100th of its start value. It uses a previous baseline measurement to derive the parameters relating to compliance. A table similar to the one shown below is created to display the T-S parameters measured at each output voltage increment.

Exercise Drivers

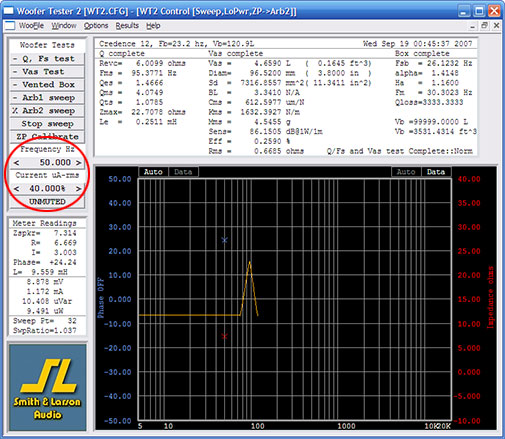

When most speaker drivers come off the assembly line, their suspension is usually a little stiff. Before the T-S parameters are measured, it is best to exercise the driver to "break in" its suspension. The WT2 has a line-level audio output for this purpose. Simply connect the WT2 line-level output to an appropriate input of a power amplifier (not included) and connect the speaker driver to the output of the amp. Then set a desired frequency and output level with the buttons circled below. Note: It is usually best to make a preliminary measurement of the driver to determine its approximate Fs then set the WT2 to this frequency during the break-in period.

The top button in the circle is used to set the frequency and it is set to 50 Hz in the illustration. The second button in the circle is used to set the output level and it is set to 40% in the illustration. The last button at the bottom of the circle is used to toggle the signal on and off (mute/unmute).

Calculate the Information Needed to Make Your Own Air-Core Inductors

The WT2 includes the handy "Design Air Core Inductor" tool shown below to help you design an air-core inductor. Enter the desired inductance in µH (microHenries), inner diameter, height, wire gauge, wire insulation thickness and temperature and the program will calculate the rest.

The "Design Air Core Inductor" dialog calculates the total number of wire turns, the DC resistance (DCR), outer diameter, number of layers, turns per layer, total wire length and weight.

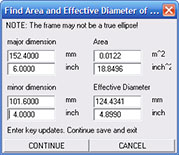

Estimate the Area and Effective Diameter of an Oval Driver

One of the required inputs for the "Vas Test" is either the piston diameter (Diam) or area (Sd) of the driver. The diameter is easy to measure if the driver is round. The area is easy to measure and calculate if the driver is square or rectangular. But what do you do if the driver has an oval shape? The answer is to use the WT2's "Find Area and Effective Diameter of ..." tool shown below. Simply enter the longest (major) and shortest (minor) dimensions of the piston and the WT2 will estimate the driver's area based on an ellipse and estimate its effective diameter (as if the driver were round).

Simulations

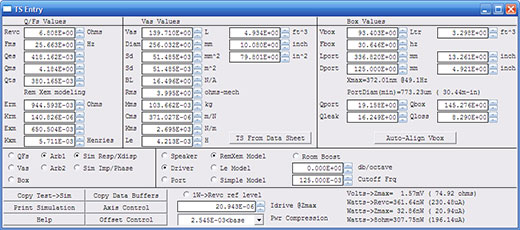

The WT2 offers a variety of ways to simulate a driver and box with the "TS Entry" dialog shown below. The driver simulation can be helpful when you need to recone a damaged driver and you want to see the effects of new cone. It can also be useful for driver designers who want to tweak driver characteristics to achieve a desired response.

The box simulation can be helpful whenever you want to model the response of a simulated or measured driver in a closed box, vented box or infinite baffle. In addition to the usual box parameters like the box volume (Vbox) and tuning (Fbox), the box simulation also allows you to control Qport, Qbox, Qleak and Qloss parameters to simulate the various kinds of losses possible in a box.

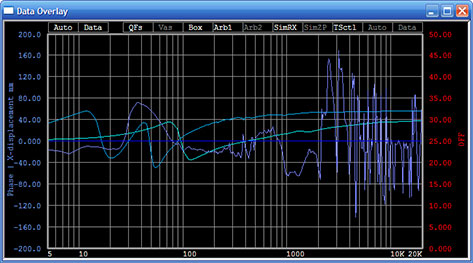

A "Data Overlay" graph is provided as a companion to the "TS Entry" dialog. It allows you plot the results of your simulations and measurements. The user can select which simulations and/or measurements to include in the graph as shown in the two samples below.

Also, the "TS Entry" dialog provides a basic "Room Boost" option to enable the user to add an approximation of the bass rise common to some acoustic spaces.

Includes a Variety of Outputs

The WT2 offers a variety of ways to save or export data from the program. Data can be saved in its native "woo" file format. These files can be loaded again later to return to a previous setup/measurement. Data can be exported to ASCII, BassBox and LMS files. The data and graphs visible on screen can also be printed.

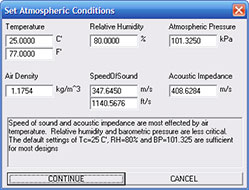

Adjustable for Atmospheric Conditions

Speaker tests can be influenced by environmental conditions such as the air temperature, relative humidity and air pressure. The "Set Atmospheric Conditions" dialog shown below enables you to adjust the WT2 for these conditions.

Compatibility

The "WooFile" menu includes an "Export to BassBox" command that creates a T-S data file that can be imported by BassBox Pro and X•over Pro. This makes it very convenient to import measured parameters into our "pro" speaker design programs. Note: BassBox Lite does not have this import capability but it is relatively easy to enter the measured parameters manually.

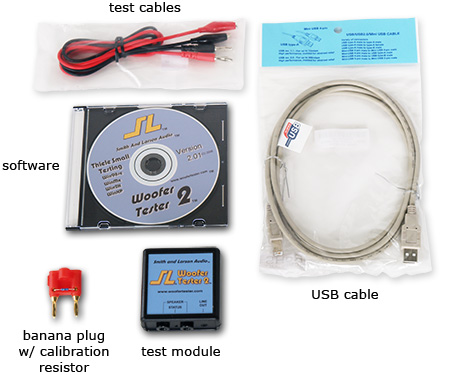

Woofer Tester 2 includes:

A WT2 measurement (test) module with USB cable, two test cables with alligator clips on one end, a banana jack with 10-ohm calibration resistor, and CD-R disc with WT2 software.

System Requirements

Microsoft® Windows® Vista, XP, 2000, Me or 98SE and a compatible computer, an available USB 1.1 or USB 2.0 port, 2 Mbytes of free hard disk space and a CD-R compatible CD-ROM or DVD drive. Note: It is possible to use the Woofer Tester 2 with Windows 7 and 8 but this may require additional steps be taken during installation and operation. Contact the manufacturer, Smith & Larson Audio, for more information.